CWL E711-Carbon Steel Flux-cored Wire

CWL E711 | GB/T10045 | E501T-1 |

AWS A5.20 | E71T-1C | |

JIS Z3313 | T49J 0 T1-1 C A-U |

Characteristics: CWL E711 belongs to carbon steel flux-cored wire for CO2 gas shielded welding, and the cross section of welding wire is "O" type docking form, suitable for all position welding, Especially when welding upward, the weld is fine and beautiful, horizontal fillet weld appearance is plane or slightly convex. Welding slag fully covers the weld, good slag removal, smooth weld formation, bright, small spatter, strong resistance to porosity. with good mechanical properties and impact toughness at low temperature. It is suitable for the post-weld heat treatment, but it should be noted that the long-time post-weld stress dissipation heat treatment will reduce the tensile strength of the weld metal, and there will be carbide precipitation in the weld metal and heat affected zone, which will affect the impact toughness of the welded joint.

Application: CWL E711 welding wire is mainly used for full-position welding of low-carbon and medium-carbon steel, single-pass and multi-pass. The general rust and the oxide film do not need to be treated, and the satisfactory effect can be obtained.

Chemical Composition of Deposited Metal

Elements wt% | C*1 | Mn | Si | S | P |

Standard Value | ≤0.12 | ≤1.75 | ≤0.90 | ≤0.03 | ≤0.03 |

Type Value | 0.04 | 1.27 | 0.61 | 0.015 | 0.010 |

Note 1: for C content, AWS A5.20: ≤ 0. 12%, JIS Z3313 and GB/T10045 : 0.18%. | |||||

Mechanical Properties of Deposited Metal

Test Items | Test Temperature ℃ | Tensile Strength MPa | Yield Strength MPa | Elongation % | Bend Test | Impact Test -20℃,J |

Standard | Room Temperature | ≥480 | ≥400 | ≥22 | See Standard | ≥27 |

As Weld | Room Temperature | 580 | 490 | 28 | Acceptable | 123 |

PWHT | Room Temperature | 527 | 435 | 27.5 | Acceptable | 101 |

Note 2: For tensile strength, AWS A5.20 and JIS Z3313 shall be 490-670 MPa, and GB/ T10045 shall be 480 MPa; Note 3: For yield strength, the requirements of AWS A5.20 and JIS Z3313 shall be as low as 390 MPa, and GB/ T10045 shall be about 400Mpa. | ||||||

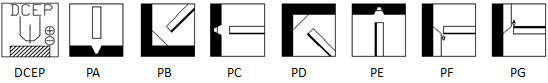

Shield Gas | Polarity & Welding Positions | |||

100%CO2 |

| |||

Welding Parameters Recommended

Diameter (mm) | PF | PF | PE | |||

Current(A) | Voltage(V) | Current(A) | Voltage(V) | Current(A) | Voltage(V) | |

0.9 | 130-280 | 20-30 | 90-180 | 16-23 | 130-250 | 20-28 |

1.2 | 150-290 | 23-30 | 150-240 | 20-26 | 150-260 | 23-26 |

1.6 | 180-400 | 25-34 | 180-260 | 22-29 | 180-310 | 23-28 |

Size and Packing

Size | S200 | S300 | BS300 | Drum100 | ||

0.9mm | 5kg | 15kg | 15kg | 150kg | ||

1.2mm | 5kg | 15kg | 15kg | 150kg | ||

1.6mm | -- | 15kg | 15kg | 150kg | ||