FM410NiMoT1-1-Stainless Steel Flux-cored

FM410NiMo | GB/T17853 | E410NiMoT1-1 |

AWS A5.22 | E410NiMoT1-1 | |

JIS Z3323 | ||

EN ISO 17633-B | TS 410NiMo C1 1 |

Characteristics: he main composition is 13Cr-NiMo, which is martensite stainless steel. It can be used to weld 13%Cr-Ni stainless steel. Because the deposited metal is a high strength martensite structure, it needs to be fully preheated at about 100 ℃. Because toughness is better than 410, so often used to weld more demanding turbine rotor, and other wear-resistant & corrosion-resistant occasions. Because of the addition of Ni or Mo, the corrosion resistance is more stable, the hardness and high temperature wear resistance are improved, and the cold cracks are effectively prevented at the same time.The flux-cored wire has excellent welding performance, smooth wire feeding, stable arc, beautiful forming, very little spatter, stable mechanical properties of deposited metal, high qualified rate of X-Ray. FM410NiMoT1-1 is stainless steel flux cored wire, suitable for full position welding.

Application: The product is suitable for welding wear-resistant and corrosion-resistant water turbine rotors, valves, etc.

Chemical Composition of Deposited Metal

Elements Wt% | C | Cr | Ni | Mn | Mo | Si | Cu | P | S |

Standard value | 0.06 | 11.0-12.5 | 4.0-5.0 | 1.0 | 0.4-0.7 | 1.0 | 0.5 | 0.04 | 0.03 |

Type value | 0.03 | 11.35 | 4.78 | 0.27 | 0.49 | 0.33 | 0.01 | 0.015 | 0.01 |

Mechanical Properties of Deposited Metal

Test items | Test Temperature ℃ | Tensile Strength MPa | Yield Strength MPa | Elongation % |

Standard | Room Temperature | ≥760 | -- | ≧15 |

As Weld | Room Temperature | 885 | -- | 17 |

Note 2: AWS A5.22:≥15%, EN ISO 17633 and GB/ T17853:≥10%. | ||||

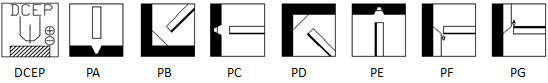

Shield Gas | Polarity & Welding Positions | |||

100%CO2 |

| |||

Welding Parameters Recommended

Diameter mm | Current A | Voltage V | Stick Out mm | Welding Speed cm/min | Gas Flow Rate L/min |

0.9 | 50-160 | 23-31 | 15-20 | 20-80 | 15-25 |

1.2 | 160-220 | 26-31 | 15-20 | 20-60 | |

1.6 | 200-300 | 26-33 | 15-20 | 20-60 |

Gas Flow Rate

Sizes | S200 | S300 | BS300 | Drum100 |

0.9mm | 5kg | 12.5kg | 12.5kg | 150kg |

1.2mm | 5kg | 12.5kg | 12.5kg | 150kg |

1.6mm | -- | 12.5kg | 12.5kg | 150kg |