FA310T0-1/4-Stainless Steel Flux-cored Wire

FA310T0-1/4 | GB/T17853 | TS310-FM211 |

AWS A5.22 | E310T0-1/4 | |

JIS Z3323 | TS310-FM211 | |

EN ISO 17633-B | TS310-FM211 | |

FA310T0-1/4 belongs to Austenite stainless steel flux-cored wire with nominal component 26.5%Cr-21%Ni. Because the weld metal is full Austenite structure, it is sensitive to hot crack tendency. The welding wire adopts special alkaline slag system and has strong crack resistance. The weld metal has excellent oxidation resistance at 900 ℃ ~ 1100 ℃, and has excellent corrosion resistance and mechanical properties. Application: this product can be widely used in welding high temperature resistant products, such as high temperature furnace, coal coking equipment, etc., and can also be used in welding composite layer surfacing welding and dissimilar steel . | ||

Chemical Composition of Deposited Metal

Elements Wt% | C | Cr | Ni | Mn | Mo*1 | Si | |

Standard Value | 0.20 | 25.0-28.0 | 20.0-22.5 | 1.0-2.5 | 0.5 | 1.0 | |

Type Value | 0.16 | 26.86 | 20.36 | 2.21 | 0.41 | 0.42 | |

Mechanical Properties of Deposited Metal

Test Items | Test Temperature ℃ | Tensile Strength MPa | Yield Strength MPa | Elongation % |

Standard | Room Temperature | ≥550 | -- | ≥30 |

As Weld | Room Temperature | 682 | -- | 39 |

Note 2: EN ISO 17633 and GB/ T17853:≥25%; AWS A5.22:≥30%. | ||||

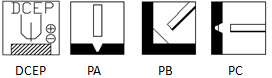

Shield Gas | Polarity & Welding Positions | |||

100%CO2 | 80%Ar+20%CO2 |

| ||

Welding Parameters Recommended

Diameter mm | Current A | Voltage V | Stick Out mm | Welding Speed cm/min | Gas Flow Rate L/min |

0.9 | 50-160 | 23-31 | 15-20 | 20-80 | 15-25 |

1.2 | 160-220 | 26-31 | 15-20 | 20-60 | |

1.6 | 200-300 | 26-33 | 15-20 | 20-60 |

Size and Packing

Size | S200 | S300 | BS300 | Drum100 |

0.9mm | 5kg | 12.5kg | 12.5kg | 150kg |

1.2mm | 5kg | 12.5kg | 12.5kg | 150kg |

1.6mm | -- | 12.5kg | 12.5kg | 150kg |