FD2209T1-1-Stainless Steel Flux-cored Wire

and higher strength & hardness.

FD2209T1-1 | GB/T17853 | -- |

AWS A5.22 | E2209T1-1 | |

JIS Z3323 | TS2209-FC1 | |

EN ISO 17633-B | TS 2209-F C1 1 |

Characteristics: FD2209T1-1 is a dual-phase stainless steel flux-cored wire with a nominal component of 22% Cr-8.5% Ni-3.5Mo-0.15N, and the protective gas is 100% CO2. The micro-structure of the weld metal is a ferrite and austenitic two-phase structure with excellent stress corrosion resistance, pitting corrosion resistance,

and higher strength & hardness. FD2209T1-1 with a special slag system formula solves the problem that it needs full positions welding under some complicated conditions, and the welding process is good, the arc is stable, the spatter is less, and the weld seam is formed beautifully.

Application:This product can be widely used in welding chemical ships, chemical equipment, water treatment equipment and other industries. Duplex stainless steel contains 22% Cr , such as 2205 (UNS S31803) welding.

Chemical Composition of Deposited Metal

Standard Value Wt% | C | Cr | Ni | Mn | Mo | Si | Cu*1 | P | S | N |

Type Value | 0.04 | 21.0~24.0 | 7.5~10.0 | 0.5~2.0 | 2.5~4.0 | 1.0 | 0.5 | 0.04 | 0.03 | 0.08~0.2 |

Standard Value | 0.023 | 22.72 | 9.19 | 0.97 | 3.19 | 0.64 | 0.01 | 0.02 | 0.02 | 0.12 |

Mechanical Properties of Deposited Metal

Test Items | Test Temperature ℃ | Test Temperature MPa | Yield Strength MPa | Elongation % |

Standard | Room Temperature | ≥690 | -- | ≧20 |

As Weld | Room Temperature | 618 | -- | 40.6 |

Note 2: AWS A5.22 :≥20%; GBT 17853 and EN ISO17633: ≥ 15%. | ||||

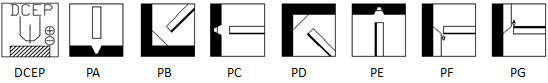

Shield Gas | Polarity & Welding Positions | |||

100%CO2 |

| |||

Welding Parameters Recommended

Diameter mm | Current A | Voltage V | Stick Out mm | Welding Speed cm/min | Gas Flow Rate L/min |

0.9 | 50-160 | 23-31 | 15-20 | 20-80 | 15-25 |

1.2 | 160-220 | 26-31 | 15-20 | 20-60 | |

1.6 | 200-300 | 26-33 | 15-20 | 20-60 |

Size and Packing

Size | S200 | S300 | BS300 | Drum100 |

0.9mm | 5kg | 12.5kg | 12.5kg | 150kg |

1.2mm | 5kg | 12.5kg | 12.5kg | 150kg |

1.6mm | -- | 12.5kg | 12.5kg | 150kg |